CASE STUDIES

MULTIFAMILY PASSIVE HOUSE

AeroBarrier allows Engineers to Easily Attain Desired Tightness for Energy Efficiency, Comfort and Livability

New Technology Makes Effective Compartmentalization Simple for New York Apartment Building Project

For New York-based architect Chris Benedict, compartmentalization is the holy grail of apartment building design. As a recognized pioneer in energy efficient building, she understands that effectively sealing the envelope that exists between apartments is not only critical for maximum energy efficiency, but it’s also key to ensuring high indoor air quality and limiting the migration of bugs, smoke, noise and other common tenant discomforts that can travel from one unit to another.

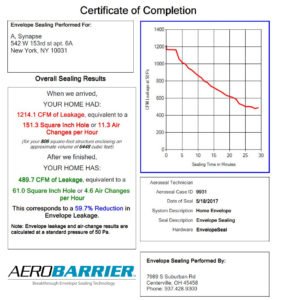

For this reason, Benedict was not happy to learn that her latest project, a newly constructed 6-story apartment building on Manhattan’s upper west did not meet the passive house-levels of tightness targeted by her design. While the manual caulking implemented by contractors got them close, it did not meet the industry’s highest standard. Now with plumbing, electrical and sheet rock installation finished, the building was nearing completion and further manual sealing was deemed impractical.

Fortunately, Benedict had heard colleagues talk about an innovative new envelope sealing technology developed at the University of California, Davis that could be applied after construction was completed. AeroBarrier was not only highly effective, she was told, but also the single-step computerized process could be dialed in to reach specific desired results. After AeroBarrier proved successfulat sealing a test unit, contractors were given the thumbs up to seal the remaining apartments within the building.

It was blowing people’s minds – mostly because monitoring compartmentalization in a multi-family building under construction is typically a very difficult, time-consuming task. The level of coordination and commitment you need to get from all contractors on the job is as critical as it is nearly impossible to achieve. With Aerobarrier, it’s simply not a problem.

It took the AeroBarrier team just 8 days to seal all 34 units to passive house levels of 0.6 air changes per hour at 50 Pascals pressure (ACH50). Blower door tests conducted after the application of the Aerobarrier technology confirmed the results – Aerobarrier was a project-saving success.